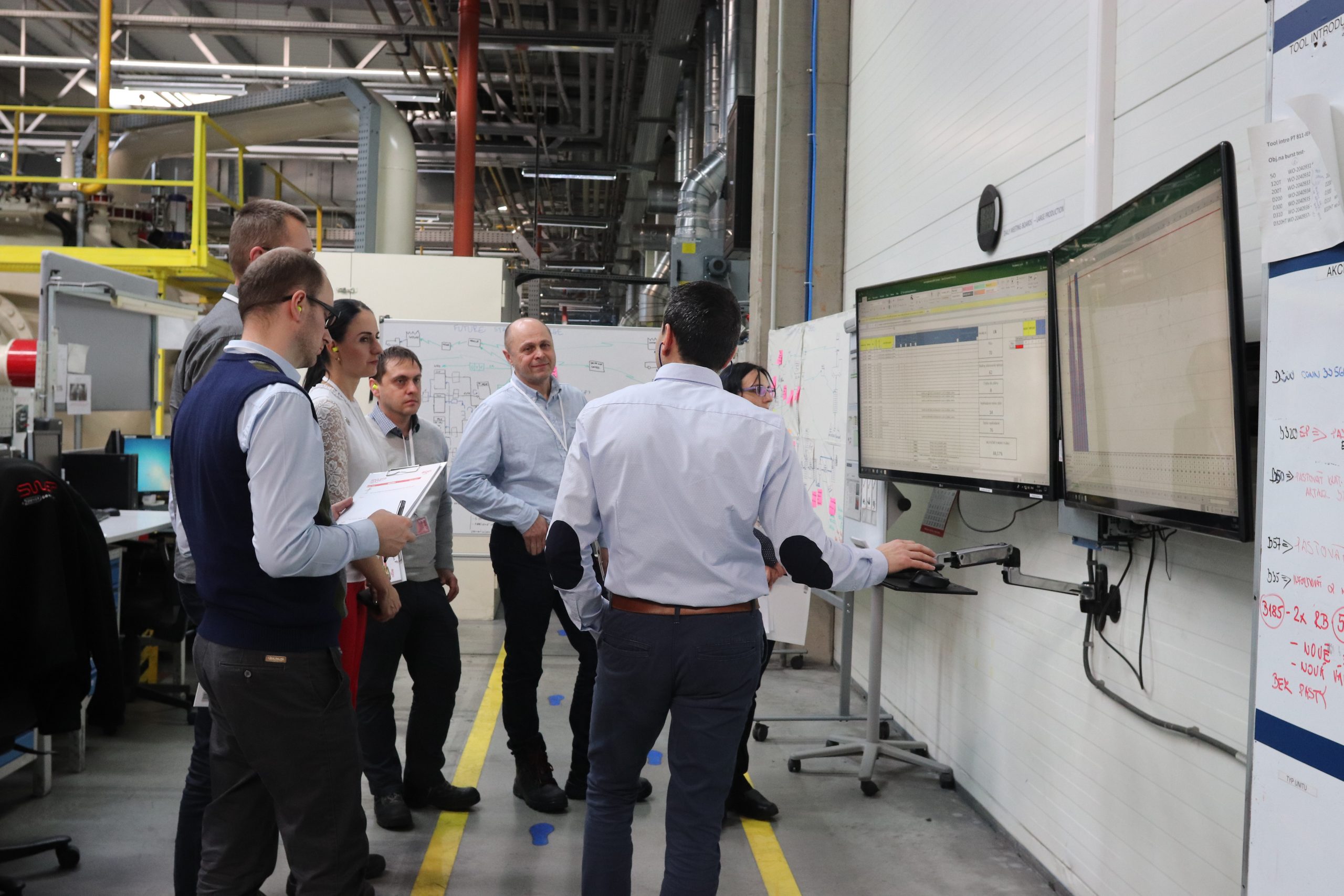

Slovakian Lean Institute (official member of Lean Global Network) organized Lean Manager Roundtable in SWEP Slovakia on 7th of February. It is a professional discussion of 15 – 20 Lean Managers of manufacturing and non-manufacturing companies. International companies like Slovnaft, Tatra Banka, US Steel, Whirpool, Bel and Lear took part on this event.

We had an opportunity to present and introduce Swep in Lean community in Slovakia. We also had a great chance to present our VSM project and talk to experts, to get their feedback, proposals and recommendations.

The main subject of this event was Value Stream Mapping – better seeing the fundamentals of our processes.

What is the main takeaway:

- VSM is tool for communication and visualization. Thanks to VSM, we can better describe and analyze current state. We are able to identify our bottleneck, waste and abnormalities in our processes more efficiently. This will help us design our future state which will respect system as a whole.

- VSM is a strategic tool with which we can set strategic actions for continuous improvement

We had a discussion about challenges and possible solutions which represent VSM process (based on practical experiences from other companies). What are the challenges?

- How to overcome administrative difficulties

- Priorities – firefighting vs continuous improvement

- Real benefits and utilization of VSM

- People/team/management involvement and support, team work

- Which kind of inputs / data we should consider, reliable data

- Right targets for future state, professional experiences

What are the possible solutions?

- Right understanding of the needs of customers and stakeholders, covering the whole stream = door to door, motivation = showing benefits on real examples of other companies, involvement from top to down and team work, strategic targets and smart KPIs, collect relevant data, Gemba walk – benchmark / visits and sharing best practices

During event we had also GEMBA walk. We got very positive feedback and some proposals for improvement. We must be proud on what we are doing.

The main takeaway for me is that we need to continue the way in which we started with our VSM project. It is not easy but it is very challenging process, as colleagues from other companies found out. However, it is a right way if we want to have systematic and continuous improvement and if we want to be better and stronger at the market.

Robert Drang

Feedback from my colleagues which also took part in this event:

Robert ZUZA:

It was a great opportunity for us/SWEP to host several managers from whole Slovakia where a lot of brains met in the small space to share the knowledge and challenges we face back home.

Among others we questioned ourselves how to get on board everybody involved during the project, what to do better/differently so people understand the change is for all of us to create better, safer and more valuable work environment.

We generally agreed that VSM is a tool for improvement but strong communication tool as well. Regular and clear reporting of the progress and results of the project is vitally important for others to join and stay on board.

Finally, it was a great marketing event for SWEP which we passed with A +.

Lionel KOUASSI:

VSM is one powerful Lean Management tool. It Provides a contextual visualization of process flows within the organization, enables identify areas creating added value and areas on which processes can be managed better. It has a great potential for generating internal savings. It was an honour for our company, Swep Slovakia, to host this seminar and to gather different types of business which similarly to us, are coping with the rather busy but interesting way of implementing VSM. We believe in the experience we have exchanged to help and better manage this journey.

Jaroslav KASARDA:

It was a great opportunity to meet people from other companies, who are engaged in value stream mapping and to share with them the theoretical knowledge as well as practical experience. All-day discussion has given me personal encouragement for further work. Feedback from the participants has shown the entire team that the steps and direction we have set up within our VSM is right. VSM is primarily a communication tool that helps to detect possible losses, bottlenecks, weaknesses, and the reasons for ineffective flows. I am therefore very glad, that we could show how we are doing in this direction and how VSM helps us to reach our goal through continuous improvement of our processes.

Jana KALMANOVA:

At the beginning the question was raised: What are my expectations from this event. My expectation: Several views on working with VSM and the evaluation.

Was my expectation fulfilled? More than that, we went through what VSM is, how to use it and what should be the result. More important for me were the views and remarks from colleagues from other production and non-production areas. During the discussion were opened problems with processing and especially of VSM leading.

What has been clearly defined is that VSM is a communication tool that can help to identify problems, weaknesses which need to be solved by teams not individual persons, so that the company can progress and achieve defined goals.

I would also like to present the feedback of our guests:

Veronika GREGORKOVA, Director / Founder of Lean Institute Slovakia

Swep team made a great job and this was clearly appreciated also by the event participants. Sometimes it is difficult to compare how far we are if we do not have objective “mirror” from different sides. That´s why Lean Manager Roundtable is so effective tool and it is core activity of our institute. Swep showed us their real involvement and wish to sustain the energy for further steps in order to reach real process optimization, it is kind of rare nowadays. Thanks team!

Milos BUGAN, VSM expert / CEO iGrow Network, s.r.o.

It’s amazing that companies are looking for a way to improve processes, and on top of that they can share their experiences with others. SWEP has fantastically confirmed this fact and has shown how they looks at improving theirs processes. I thank SWEP and their staff for having spoken openly about what they have done and what is still waiting for them.

Lots of thanks to all my colleagues which helped me prepare this event.

Robert Drang